How to Move from Spreadsheets to a CMMS Without Losing Your Data

If you’re managing your facility’s maintenance through spreadsheets, you’re not alone. Many facility managers rely on tools like Excel or Google Sheets to track assets, log maintenance work, and keep up with day-to-day tasks. Spreadsheets are easy to start with and flexible enough to do a lot.

But as your team, equipment, and workload grow, these files start to feel too small for the job. Work gets harder to track, mistakes become more common, and you start losing time chasing information instead of solving problems.

That’s when a Computerized Maintenance Management System (CMMS) comes into play. A CMMS helps you organize all your maintenance work in one place, schedule tasks automatically, track history, and make better decisions based on real data. The only catch? You’ve got years of important data stored in spreadsheets. And you don’t want to lose any of it. However, the good news is, you don’t have to. This blog will walk you through the entire process of switching to a CMMS, or you could say, moving from spreadsheets to a CMMS, step by step, in a way that keeps your data safe and your work flowing smoothly.

Why Spreadsheets Start to Hold You Back: Understanding the Limitations of Spreadsheets

Spreadsheets are helpful at the beginning, but they’re not designed to support growing maintenance operations. Over time, they become:

- Hard to keep up to date: You need to manually update every entry.

- Tricky to share: One person editing at a time can lead to confusion and lost data.

- Easy to break: A small formula error can throw off your entire sheet.

- Not built for teams: Tracking who did what, when, and where gets messy fast.

- Limited in features: You don’t get alerts, mobile access, work order tracking, or performance dashboards.

If you’re spending more time managing spreadsheets than maintaining equipment, it’s time for a change.

What Is a CMMS and How Can It Help?

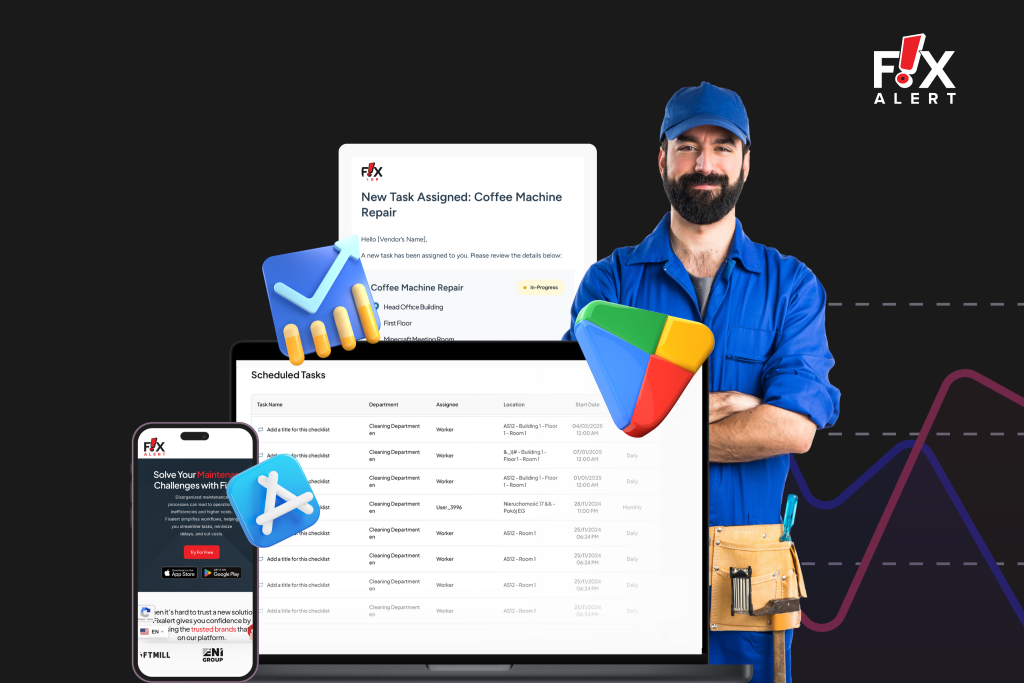

A CMMS (Computerized Maintenance Management System) is software that helps you manage everything related to maintenance, from tracking work orders to scheduling preventive tasks to keeping up with inventory and asset details.

With a CMMS, you can:

- Store all your equipment and maintenance data in one place

- Assign tasks and get real-time updates from your team

- Set up automatic reminders for upcoming work

- Log maintenance history for inspections or audits

- Use your phone or tablet to check or update work on the go

- Pull reports to understand what’s working and what needs attention

It’s like giving your facility team a powerful control panel that simplifies the daily workload and reduces human error. If you’re new to the concept, read our blog: What is a CMMS? A Simple Guide for Facility & Maintenance Teams to understand how it works and why it matters

A Simple Plan to Move from Spreadsheets to a CMMS

You don’t have to scrap your spreadsheets and start from zero. You just need a clear plan and the right steps. Here’s how you can make the switch without losing your valuable data.

Step 1: Review the Spreadsheets You’re Using

Start by listing out all the Excel spreadsheets you rely on for maintenance tasks. This may include:

- Asset records

- Maintenance schedules

- Work orders

- Spare parts or inventory

- Contact lists for vendors or contractors

- Cost tracking or budget sheets

Then, check what’s still accurate and what’s outdated. Some files may contain retired assets, incomplete tasks, or duplicate records.

To go smoothly, clean up as you go. Remove unnecessary sheets, combine similar ones, and make sure the key information is still there.

This step helps you figure out what data is worth keeping and what can be left behind.

Step 2: Choose a CMMS That Fits Your Team

There are many CMMS platforms out there, and they all come with different tools. You’ll want to pick one that matches your daily needs, works well for your team size, and is easy to set up.

Look for features like:

- Simple data import tools

- Mobile access for field teams

- Preventive maintenance scheduling

- Work order tracking

- Custom fields to match your current system

- Easy-to-use dashboards and reports

- Responsive support and training options

Ask for a demo or trial before you decide. Try uploading some sample data or running through a few real tasks to see how it feels.

Step 3: Match Your Data to the New System

Now, take your cleaned spreadsheets and start aligning them with how your CMMS stores information. For example:

- Your equipment list might go into the assets section

- Monthly tasks could become scheduled maintenance plans

- Completed work orders might be saved as historical records

Rename your spreadsheet columns to match the terms your CMMS uses. This helps the system place your data in the right fields automatically.

Also, check if the software needs certain fields to be filled, like:

- Asset ID or name

- Location

- Assigned technician

- Maintenance frequency

Filling in this information now will save you time and trouble later.

Step 4: Get Your Data Clean and Ready

This step is all about double-checking your data so it’s ready for import.

Make sure:

- Dates are in the same format (such as 2025-06-29)

- Equipment names are consistent (don’t mix “Boiler1” with “boiler 1”)

- There are no missing or empty columns

- Status fields use the same words (like “Open”, “In Progress”, “Closed”)

- Units of measurement are consistent (hours, days, etc.)

Keep a backup of your original files just in case you need to start over or refer back later.

Step 5: Try a Small Test Import First

Before you move everything over, try importing just 10 or 20 rows of data into your new CMMS. This helps you spot any formatting issues, missing fields, or other small problems.

After the test, check how the data looks:

- Are the asset details showing up properly?

- Are the maintenance dates and technicians assigned correctly?

- Are any fields blank or mismatched?

Fix what needs fixing, then move on to the full import.

Step 6: Import Everything with Care (Your CMMS Data Migration Step)

Once your test looks good, you’re ready to bring in the rest of your data. You can usually upload your spreadsheets as CSV files directly into the system. Some CMMS tools also offer help with this step through guided onboarding.

Take your time during this process. Confirm that each part of your data is going into the right place, from work history to spare parts.

After the import, walk through each module and make sure:

- Assets are listed clearly

- Scheduled tasks are set up and visible

- Work orders and past records are attached correctly

- Spare parts are showing the right counts

Step 7: Train Your Team to Use the New System

Even the best system won’t work if your team doesn’t know how to use it. Once your data is in, it’s time to bring your technicians and managers on board.

Start with short, hands-on sessions that show:

- How to find and complete a work order

- How to update asset information

- How to log maintenance notes

- How to receive alerts or reminders

- How to use the mobile app (if available)

Keep it simple at first. Focus on just what each role needs to know to get started. You can always expand later.

Step 8: Set Up Preventive Maintenance Schedules

One of the biggest benefits of a CMMS is the ability to plan ahead. Now that your data is organized, start building recurring maintenance tasks for your key equipment.

Here’s what you can do:

- Create tasks for things like filter changes, inspections, lubrication, and calibration

- Set the schedule (for example: every month, every 500 hours, every 90 days)

- Assign tasks to the right technician

- Add clear instructions or checklists

- Attach manuals, safety steps, or photos if needed

This will help your team stay on top of maintenance and prevent unexpected breakdowns.

Step 9: Watch How It’s Working and Make Improvements

After a few weeks of using the CMMS, check in with your team and your CMMS data. Look at how things are going:

- Are tasks being completed on time?

- Are technicians using the system easily?

- Are any fields being ignored or forgotten?

- Are the reports showing helpful insights?

Use what you learn to fine-tune the system. You might need to adjust forms, rename categories, or set up new reminders.

This part takes a little patience, but it’s worth it. Every small improvement makes the system work better for your team.

Step 10: Keep Your Data Safe and Up to Date

Even though your CMMS is in the cloud, it’s smart to keep things secure and organized.

Here’s how to stay on track:

- Set clear user roles so only the right people can make changes

- Turn on security features like two-factor login if available

- Export monthly reports or data summaries for backup

- Regularly review your system to retire old assets or update schedules

By keeping your data management clean and current, your CMMS will stay reliable for years to come.

Wrapping Up

Making the move from spreadsheets to a CMMS is a big step, but it’s one that pays off in better efficiency, fewer surprises, and more control over your facility’s operations. You don’t have to do it all in one day. Start with the basics, involve your team, and build on it over time. You’ll not only keep your valuable data, but also turn it into something more useful, more reliable, and easier to manage.

You don’t have to start over from scratch. With Fixalert, you can bring your data, your team, and your process into one place, without losing a thing. The transition from spreadsheets can be fast, stress-free, and well worth it.